QVAL Group - expanding the LIGHT of possibilities and potential for projects and needs by providing innovative solutions through a unique brand of Engineering support.

WHAT WE ARE ABOUT :

We ourselves are always evolving - Currently have a patent pending for printing using NO consumables- example displayed in video on following page.

Assisting to bring product to market in shorter time frame

Providing support to utilize scrap, expand other markets for current products

Making better use of TIME, Resources and FINANCES

Facilitating manufacturing (manual to Automation) process

Studying and analyzing current operation(s) and producing list of suggestions for improvement and better utilization of resources

Implementing Cost Savings program for Manufacturing and Non-manufacturing activities

Provide methods that help people generate solutions for problems, issues, or improvements . Recommend people take small time outs during the day to engage different parts of the brain to come up with solutions or ideas for problems, or issues.

NOTE:

Everything happens with a TEAM formation including those affected by the process along with supporting department. CREDIT is spread among team members

NOTE II

The Best Praise we receive is upon project completion we hear words like, “wherever you go, I or we would like to go too.” Or, ” I’ve leaned a lot from you.”

The QVAL Group consist of contract engineers with a unique blend of background in Manufacturing, Process, Industrial, Sterilization, Packaging and Cost savings. We’ve helped individual, small to large size companies so size is not a variable. Where cost may be a restriction, we can train and refer people to companies that will bring about their own innovations and creations and let evolve their ideas through hands on vetting.

We work alongside the client existing resources to minimize extraneous expenditures and meet the specifications required by the FDA and ISO. No project is too small for us to look at, guide, mentor or take on.

WHY NOT SEE IF QVAL GROUP ENGINEERING CONSULTING WALKS THE TALK—and brings Quality and Value to your project(s) !!

Our newest Patent Pending Marking system requires no labels or inks (saving the Environment, warehouse requirements, maintenance, and paperwork. ) We also provide any type of packaging equipment to meet your specifications and speeds.

“We can provide Horizontal Thermo-Form-Fill-Seal” or form fill machines

“New Laser Marking uses NO consumables. This example, shows four (4) complete labels in total of 2 seconds, printed on HDPE film.

“New Laser Marking uses NO consumables, printed on Tyvek (R). This example shows 6 complete labels in 4 seconds.

Make it HAPPEN!

Make it HAPPEN!

It all begins with an idea or a need. Maybe you thought something might work and you wanted to try or you saw something that was NOT working and you want to come up with a solution. Following 2 pages are a miniature presentation to stimulate your thoughts as you read on.

How do you help Scientist design a full scale facility to grow human tissue for example, single skin cell (Fibroblast) and expand to size of football Field? What equipment do you design to handle coming from a Petri Dish to full size manufacturing?? We did…

Bio-Reactor built from Scrap material found in Bone Yard to Expand Fibroblast while expanding in the incubator

New Water purification System for 3rd world countries

How do you accomplish the task of solving design issues for Stainless Steel - Semi-automated TIG weld cells, design and build work stations, including the cooling and transporting systems and put together a new factory in an empty building in 4 months plus qualify the NEW product of the Clients Customer (Validation proof with QC & QA written documents generated and approved) ???

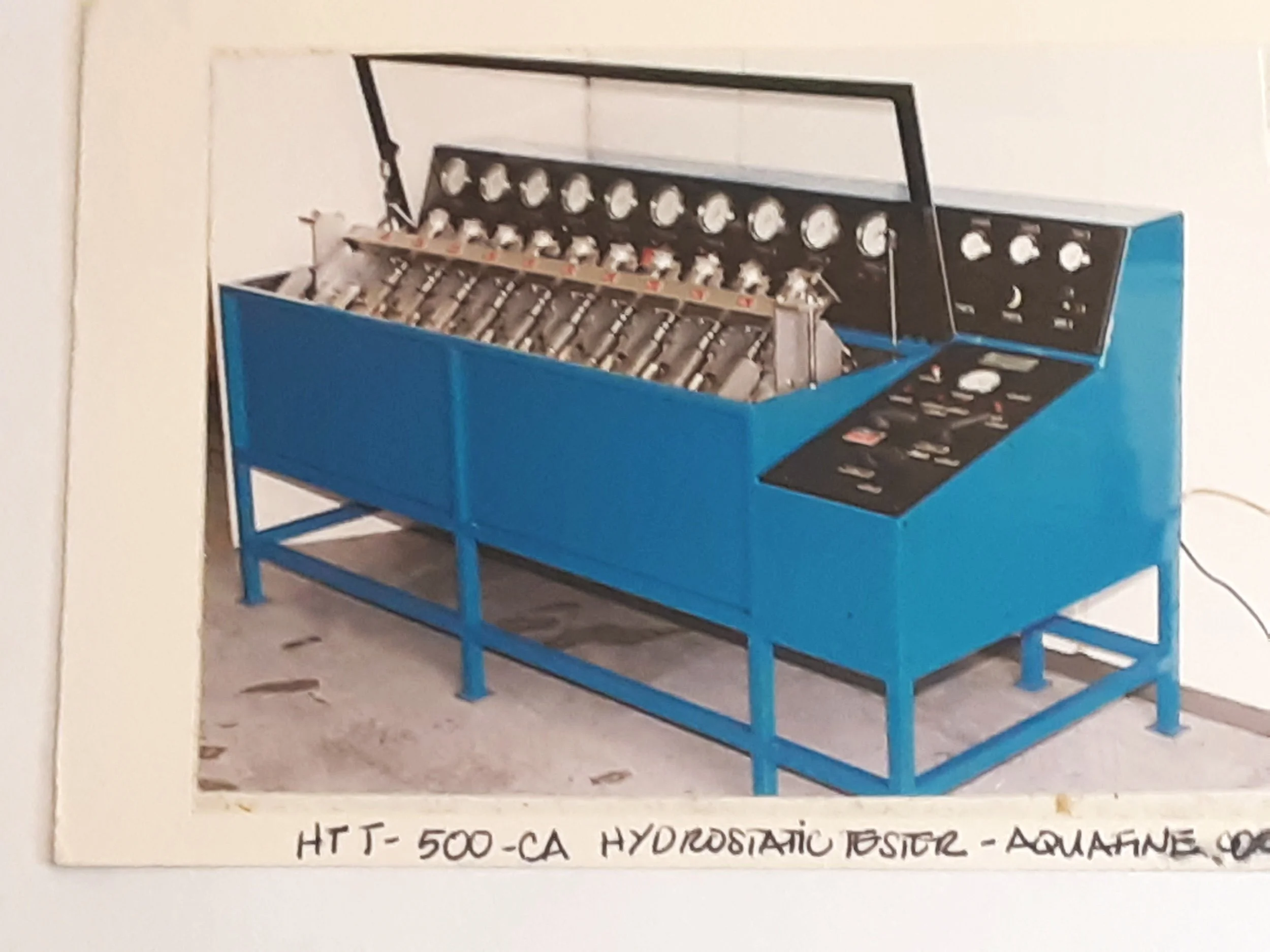

How do you change a Hydraulic Testing system that takes 2 minutes to check for leaks checking one device at a time.???

We will give you the answer - we went from Fluid fill to air fill and built a 12 unit system that took 12 seconds to check to leaks. Once leak(s) were found they were checked on a one up system which produced a 100% savings on parts in addition to the time savings.

How do you help - non manufacturing support reduce their work load??

Proposed a system to let the computer handle part of the work load the office personnel was doing manually. Once the programmers designed and implemented it reduced the work load of 6 hours at one of the DESKS!! Which was okay because the person was already handling 2 jobs full time.

Make it HAPPEN continue!

What critical steps do you need to take when a Leak in an IV set component at the Needless insertion site occurs in the field and the company needs the quickest action to solve the issue before the FDA shuts the product down??

1 million per day is produced and shipped by the company. We came up with a most unique way to find the issues at the molding, Automated assembly and testing steps.

Evaluate the longest and most troublesome stations before building the automated process so you can minimize the downtime and stoppage. Have you done this ??

If not, we can help, even finding steps to test the quality of molded products before assembly

How do you guarantee seal integrity and automate count of the number and load for the operator??

Ask us how we modified an existing client’s pouch sealer to fulfill this need.

COST SAVINGS are everywhere. It has to looked and thought about with different skills — We teach and help companies and individual bring that to reality. In addition we help establish rewards, celebrations and incentives.

We’ve taken scrap and made products and developed processes that companies are still using after more than 20 years. But, the 1st step begins with you!!

MEET THE TEAM

Chris Chemberlen - AAMI Member

Validation, Package & System Design including equipment, marking, printing & implementation

Douglas D. Davie - AAMI Member

Sterilization Validation Services for state-of-the-art ANSI/ AAMI/ ISO Validation